Why do we sterilize with Electron Beam instead of Gamma Radiation?

In the field of in-vitro diagnostics (IVD), the importance of sterilization cannot be overstated. Proper sterilization ensures that the products used are free from harmful microorganisms, guaranteeing reliability and safety for both patients and healthcare professionals. One of the popular methods of sterilization is through the use of radiation, specifically Electron Beam (e-beam) technology or Gamma Radiation. In this article, we will explore why Suzhou Ace Biomedical Technology Co., Ltd. chooses to sterilize IVD consumables with Electron Beam instead of Gamma Radiation.

Suzhou Ace Biomedical Technology Co., Ltd. is a leading manufacturer and supplier of IVD consumables in the global market. With a commitment to quality and innovation, the company aims to contribute to the advancement of healthcare by providing reliable and safe products. One of the crucial steps in their manufacturing process is sterilization, and they have chosen e-beam technology as their preferred method.

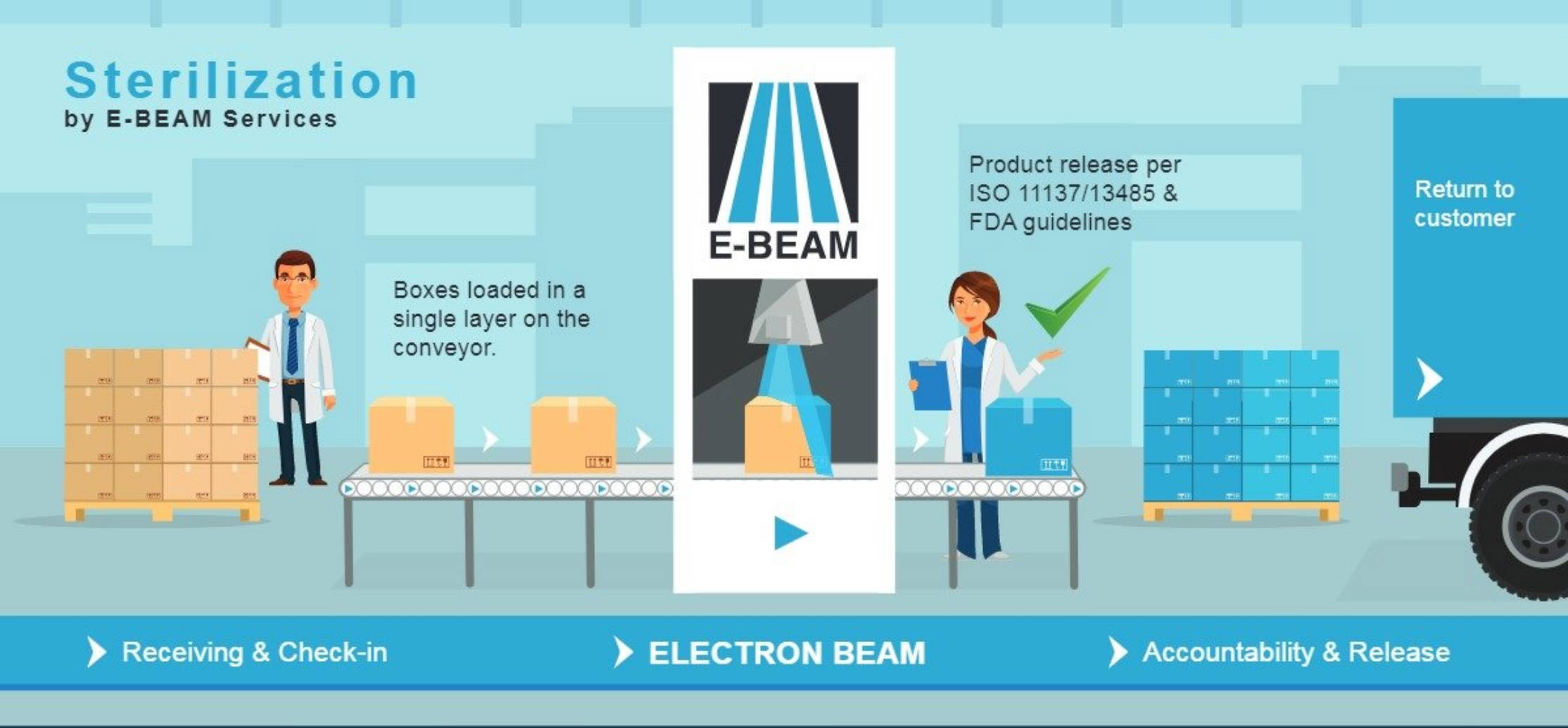

E-beam sterilization involves using high-energy electron beams to eliminate microorganisms and other contaminants on the surface of the products. Gamma Radiation, on the other hand, uses ionizing radiation to achieve the same purpose. So why does Suzhou Ace Biomedical Technology Co., Ltd. opt for e-beam sterilization?

Firstly, e-beam sterilization offers several advantages over Gamma Radiation. One of the key benefits is its ability to provide uniform sterilization throughout the product. Unlike Gamma Radiation, which may have uneven distribution and penetration, e-beam technology ensures that the entire product is exposed to the sterilizing agent. This reduces the risk of incomplete sterilization and ensures a higher level of product safety.

Additionally, e-beam sterilization is a cold process, meaning it does not generate heat during sterilization. This is particularly important for IVD consumables, as excessive heat can damage sensitive components such as reagents and enzymes. By using e-beam technology, Suzhou Ace Biomedical Technology Co., Ltd. is able to maintain the integrity and functionality of their products, ensuring accurate and reliable diagnostic results.

Another advantage of e-beam sterilization is its efficiency and speed. Compared to Gamma Radiation, which may require longer exposure times, e-beam technology offers faster sterilization cycles. This allows Suzhou Ace Biomedical Technology Co., Ltd. to increase their production efficiency and meet the growing demands of the market without compromising on product quality.

Furthermore, e-beam sterilization is a dry process, eliminating the need for additional drying steps. This saves both time and resources, reducing the overall production costs for Suzhou Ace Biomedical Technology Co., Ltd. By choosing e-beam technology, they can provide cost-effective IVD consumables without compromising on sterility and safety.

It is worth noting that Suzhou Ace Biomedical Technology Co., Ltd. considers not only the efficacy of sterilization but also the environmental impact. E-beam technology does not produce any radioactive waste, making it a more environmentally friendly option compared to Gamma Radiation. This aligns with the company’s commitment to sustainability and responsible manufacturing practices.

In conclusion, Suzhou Ace Biomedical Technology Co., Ltd. chooses to sterilize IVD consumables with Electron Beam (e-beam) technology instead of Gamma Radiation due to its advantages in uniform sterilization, cold process, efficiency, speed, and environmental friendliness. By adopting e-beam sterilization, the company ensures the safety, reliability, and cost-effectiveness of their products, contributing to the advancement of in-vitro diagnostics and healthcare as a whole.

Post time: Aug-24-2023