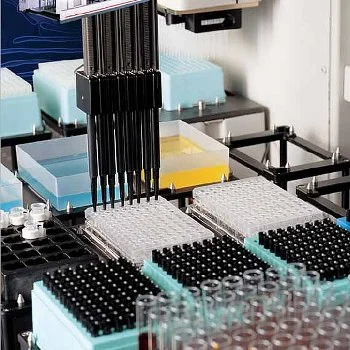

Automated Liquid Handling refers to the use of automated systems instead of manual labor to transfer liquids between locations. In biological research labs, standard liquid transfer volumes range from 0.5 μL to 1 mL, though nanoliter-level transfers are required in some applications. Automated liquid handling systems vary in size, complexity, performance, and cost.

From Manual to Automated Liquid Handling

The most basic tool is the manual pipette—a handheld device requiring repetitive user intervention for each step (aspiration and dispensing). Prolonged use can lead to repetitive strain injuries like carpal tunnel syndrome.

Electronic pipettes represent the next evolutionary step. Both manual and electronic pipettes can have adjustable/fixed volumes and 1–16 channels. While multi-channel electronic pipettes increase throughput compared to manual single-channel pipettes, they remain limited by human input. Automated dispensers overcome this by simultaneously distributing liquid into all wells of a microplate (e.g., 96- or 384-well plates).

Modern lab assays often require multi-step “workflows.” Automated liquid handling workstations integrate modules (e.g., shakers, heaters) and software to execute complex protocols.

Modern lab assays often require multi-step “workflows.” Automated liquid handling workstations integrate modules (e.g., shakers, heaters) and software to execute complex protocols.

- Entry-level systems are compact with user-friendly software but limited flexibility.

- Advanced systems support modular upgrades, expanded workflows, and integration with other lab equipment.

Key factors for selecting liquid handling technology include:

(i) Throughput, (ii) Workflow complexity, (iii) Budget, (iv) Lab space, (v) Sterility/cross-contamination control, (vi) Traceability, (vii) Precision.

Precision in Automated Liquid Handling

Precision depends on liquid properties, pipetting technique, and (for manual systems) user skill. Liquid properties—affected by temperature, pressure, and humidity—include:

- Viscosity (flow behavior)

- Density (mass/unit volume)

- Adhesion/cohesion (stickiness)

- Surface tension

- Vapor pressure

Advanced systems adjust parameters to account for these properties:

(i) Aspiration/dispensing speed,

(ii) Air gaps (blowout/air displacement),

(iii) Pre-aspiration dwell time,

(iv) Tip withdrawal speed.

Major Pipetting Technologies

Classified by liquid propulsion mechanisms:

- Air Displacement

- Liquid Displacement

- Positive Displacement

- Acoustic Technology

Evolution Timeline

Manual Pipette (Single-Channel) → Manual Pipette (Multi-Channel) → Electronic Pipette → Automated Dispenser → Entry-Level Workstation → Modular Automated Workstation

| Pipetting Technology | Key Features | Primary Applications |

| Air Displacement | Air cushion separates the moving piston from the sample | Highly stable for volumes within 0.5–1,000 μl |

| Liquid Displacement | Air cushion separates system liquid from the sample | Typically used with fixed stainless steel washable tips; ideal for steps requiring pierced tubes |

| Positive Displacement | Direct contact between moving piston and sample | Preferred for high-viscosity and volatile samples |

| Acoustic Technology | Contactless liquid transfer using acoustic energy (sound waves) | Ultra-low volumes (down to nanoliter range) |

Post time: May-12-2025