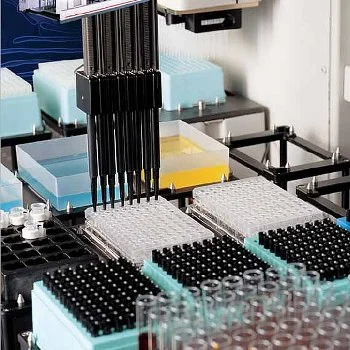

Ho sebetsana le Mokelikeli o Ikemetsenge bua ka tšebeliso ea litsamaiso tse itirisang sebakeng sa mosebetsi oa matsoho ho fetisetsa maro lipakeng tsa libaka. Lilab tsa lipatlisiso tsa baeloji, methamo e tloaelehileng ea phetiso ea mokelikeli e tloha ho0.5 μL ho isa ho 1 mL, leha ho hlokahala phetiso ea boemo ba nanoliter lits'ebetsong tse ling. Sistimi ea ho sebetsana le mokelikeli o ikemetseng e fapana ka boholo, ho rarahana, ts'ebetso le litšenyehelo.

Ho tloha ho Manual ho ea ho Automated Liquid Handling

Sesebelisoa sa motheo ka ho fetisisa kepipette ea letsoho- sesebelisoa se ts'oaroang ka letsoho se hlokang ho ipheta-pheta ha mosebelisi mohatong o mong le o mong (takatso le ho fana). Tšebeliso ea nako e telele e ka lebisa likotsing tse pheta-phetoang tse kanglefu la carpal tunnel syndrome.

Li-pipette tsa elektronikeemela mohato o latelang oa ho iphetola ha lintho. Ka bobeli li-pipette tsa letsoho le tsa elektroniki li ka ba le melumo e feto-fetohang / e tsitsitseng le likanale tse 1-16. Le hoja li-pipette tsa elektronike tse nang le mechine e mengata li eketsa phallo ha li bapisoa le li-pipette tsa mochine o le mong, li ntse li lekanyelitsoe ke ho kenngoa ha batho.Lisebelisoa tse ikemetsenghlola sena ka ho abela mokelikeli ka nako e le 'ngoe lilibeng tsohle tsa microplate (mohlala, lipoleiti tsa liliba tse 96 kapa tse 384).

Litlhahlobo tsa sejoale-joale tsa lab hangata li hloka "methati e mengata ea mosebetsi".Lits'ebetso tsa ho sebetsana le mokelikeli o ikemetsengkopanya li-module (mohlala, li-shaker, heaters) le software ho phethahatsa liprothokholo tse rarahaneng.

Litlhahlobo tsa sejoale-joale tsa lab hangata li hloka "methati e mengata ea mosebetsi".Lits'ebetso tsa ho sebetsana le mokelikeli o ikemetsengkopanya li-module (mohlala, li-shaker, heaters) le software ho phethahatsa liprothokholo tse rarahaneng.

- Litsamaiso tsa boemo ba ho kenali kopane le software e bonolo ho basebelisi empa ha li feto-fetohe le maemo.

- Mekhoa e tsoetseng pelets'ehetsa lintlafatso tsa modular, phallo e atolositsoeng ea mosebetsi, le ho hokahana le lisebelisoa tse ling tsa lab.

Lintlha tsa bohlokoa tsa ho khetha theknoloji ea ho sebetsana le metsi li kenyelletsa:

(i) Ts'ebetso, (ii) Ho rarahana ha mosebetsi, (iii) Tekanyetso, (iv) Sebaka sa Lab, (v) Taolo ea tšilafalo / tšilafalo, (vi) Traceability, (vii) Precision.

Precision in Automated Liquid Handling

Ho nepahala ho ipapisitse le thepa ea mokelikeli, mokhoa oa ho tsamaisa lipeipi, le (bakeng sa litsamaiso tsa matsoho) tsebo ea mosebelisi. Lintho tsa mokelikeli-tse angoang ke mocheso, khatello le mongobo-li kenyelletsa:

- Viscosity(boitšoaro ba ho phalla)

- Botenya(boima ba boima / yuniti)

- Kgomarelo/kopano(ho khomarela)

- Ho tsitsinyeha ha bokahodimo

- Khatello ea mouoane

Sistimi e tsoetseng pele e fetola liparamente ho ikarabella bakeng sa thepa ena:

(i) Takatso/ lebelo la ho fana,

(ii) Likheo tsa moea (ho phatloha / ho falla ha moea),

(iii) Nako ea ho lula pele ho takatso,

(iv) Keletso ea ho tlohela lebelo.

Theknoloji e Meholo ea Lipeipi

E arotsoe ka mekhoa ea ho tsamaisa metsi:

- Phallo ea Moea

- Phallo ea Mokelikeli

- Phallo e Ntle

- Theknoloji ea Acoustic

Evolution Timeline

Pipette ea Manual (Channel e le 'Ngoe) → Pipette ea Manual (Liteishene Tse Ngata) → Pipette ea Elektroniki → Setsi se Ikemetseng → Setsi sa Mosebetsi sa Kena → Modular Automated Workstation

| Theknoloji ea liphaephe | Likarolo tsa Bohlokoa | Lisebelisoa tsa mantlha |

| Phallo ea Moea | Mosamo oa moea o arola piston e tsamaeang le sampole | E tsitsitse haholo bakeng sa mefuta e ka hare ho 0.5-1,000 μl |

| Phallo ea Mokelikeli | Mosamo oa moea o arola mokelikeli oa sistimi ho sampole | Ka tloaelo e sebelisoa ka malebela a tsitsitseng a tšepe e sa hloekang; e loketseng mehato e hlokang li-tubes tse phuntsoeng |

| Phallo e Ntle | Khokahano e tobileng lipakeng tsa piston e tsamaeang le sampole | E ratoa bakeng sa mehlala e phahameng ea viscosity le e feto-fetohang |

| Theknoloji ea Acoustic | Phetisetso ea metsi e sa amaneng le ho sebelisa matla a acoustic (maqhubu a molumo) | Bophahamo bo tlase haholo (ho fihla ho nanoliter) |

Nako ea poso: May-12-2025